Automated solutions

Automated solutions are today primarily used with AGVs, but may become more common in other environments as well. The advantages are a fast, safe and easy handling of the energy supply for trucks and other vehicles.

A fully automatic battery replacement system is an integrated component in a larger system with load carriers, transport planning, warehouse logistics and business system. We always look at the conditions, plan, manufacture and install in close collaboration with the customer and other suppliers. Each project has unique conditions and the solutions therefore it looks a little different from time to time.

JOPRO Automatic replaces batteries on the AGVs and is completely automatic. No operator needs to be involved. A battery change only takes 3-5 minutes, which means that the AGV’s downtime can be kept down to less than half an hour per day.

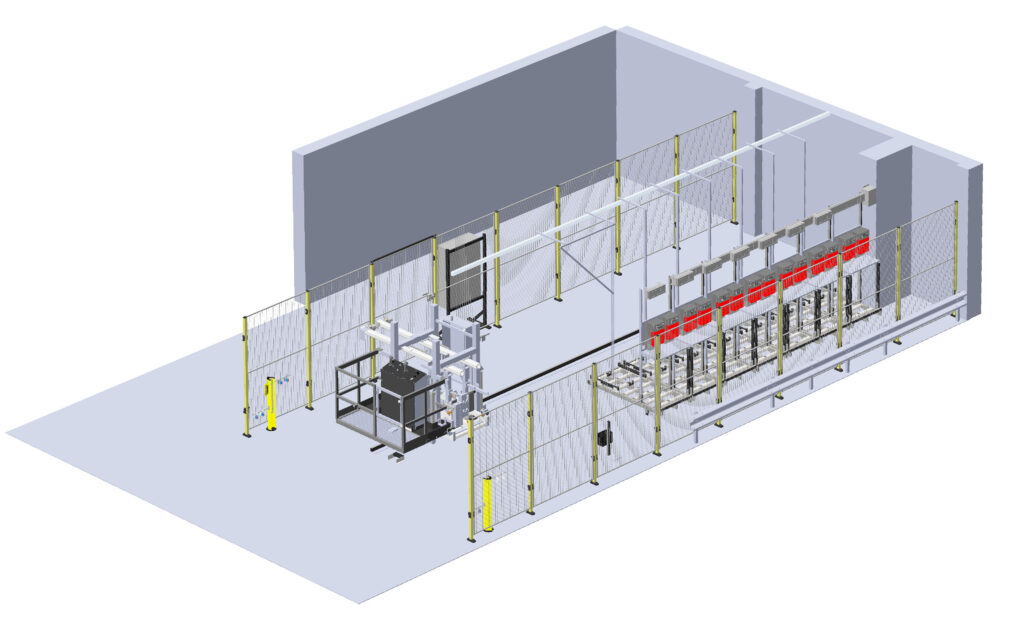

Battery replacement takes place within a fenced area equipped with a light curtain. If a person tries to enter the battery replacement area, the system is then immediately interrupted and all mechanical movement stops. JOPRO Automatic communicates with the AGVs via a signal interface. The battery changer is equipped with a complete operator cage and control panel for use in manual mode.

All functions are controlled by PLC and use the same technical solutions as our well-proven JOPRO Transfer. Laser and camera technology are used for positioning.

We have completed about ten projects in the USA, Japan, Great Britain, Holland and Germany.